We direct major investments into key technologies to ensure energy efficiency, robustness and especially the consistent qualities of the fans. Automated assembly lines play an important role here and are a prerequisite for providing traceable process control.

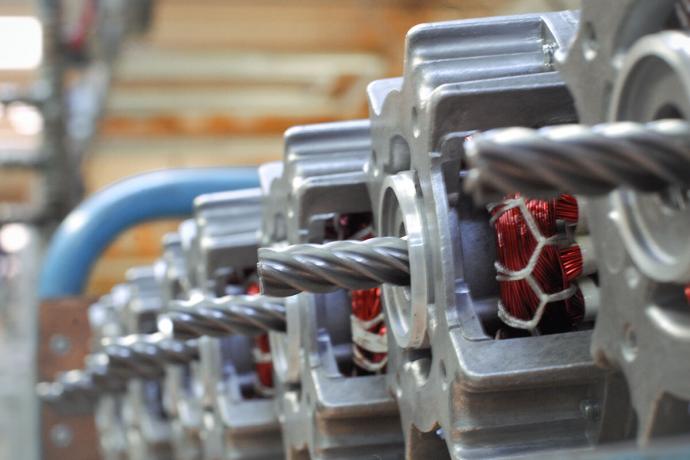

Modern technologies of winding, forming and impregnating stator windings ensure the fans’ long life. And the technologies of the final assembly of fans and the mechanical balancing of the rotor stack with the propeller of the fan give excellent vibro-acoustic characteristics.

All key machining operations on components and sub-assemblies of fans and all automated processes of the assembly of finished fans are quality-controlled. In the case of the most complex EC fans with integrated electronic drives, the process parameters together with the testing parameters and fan electronic settings are recorded in a unified database. Using the 2D code of the label of each fan allows us to access all of the specific parameters of its settings and measured process values.

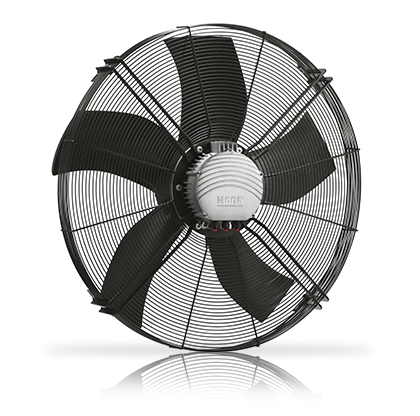

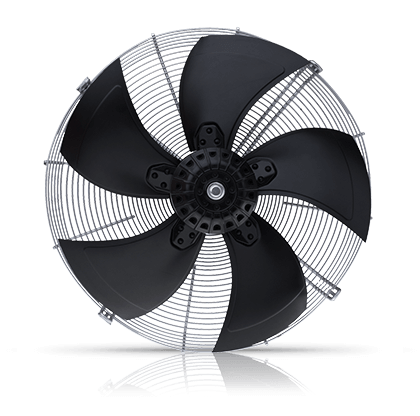

If a client specially wishes, the fan’s appropriateness can also be confirmed by measurements of the aerodynamic and vibro-sound characteristics and its functionality by testing its thermal sustainability.